|

| The set-up for making an alginate mold. |

|

| Alginate is a powdery blue material made from seaweed. |

|

| For our class purposes, we are using a 1:2 ratio of alginate to water. Translated into numbers, that is 67 oz of alginate and 100 oz. of water. |

|

| Water goes into the bowl first, then the powdered alginate gets added next. |

|

| Mix by hand or use the LOWEST setting on the blender... |

|

| ...the lowest setting on the blender will keep air bubbles to a minimum... |

|

| Have someone hold the container as you pour in the alginate. |

|

| Have your "hand model" practice their hand position BEFORE they immerse their hand into the alginate. |

|

| We put a large coffe can underneath Robert's right arm so he could comfortably lean against it and keep his hand from moving around too much in the alginate. |

|

| Amazing detail in alginate. |

|

| I insert a long stick in between the edge of the alginate and the plastic "mother mold" to break the vacuum seal holding the alginate in the mother mold. |

|

| Tip everything over sideways so gravity will work with you in removing the alginate mold from the mother mold. |

|

| Have someone ready to catch the alginate as it emerges from the mother mold. |

|

| Gently spreading open the mold to expose the fingers. |

|

| Brooke holds the alginate mold in place so nothing breaks. |

|

| I use a q-tip to measure the depth of the fingers, then mark the position with a sharpie... |

|

| ...then I transfer this measurement to my plastic hose... Not so essential when the fingers are straight in the mold, but VERY HELPFUL if the fingers are curved back upward! |

|

| I've prepared little "separators" in advance of this demo - stiff paperboard and bamboo skewers. |

|

| Shake the can well for 30 seconds then do a test run. Use as light a touch as possible. |

|

| Coral holds the separator in between the fingers in the alginate so I can fill the fingers one at a time, insuring that there is foam going all the way down to the fingertips. |

|

| Filling all the fingers. |

|

| After the fingers and thumb have been filled, put the mold back together and fill it up the rest of the way. |

|

| ...then gently put the alginate mold back into the plastic mother mold. |

|

| Sideways works well because you want to be gentle and go easy with it. |

|

| You can use the stick again to get the alginate back into the mother mold. |

|

| Then, top it off with more foam. |

|

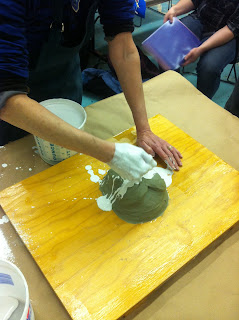

| One-piece Plaster Mold Demo begins with a plasticene (non-drying, oil-clay) model on a well urethaned bottom board. |

|

| I've washed the surface of the bottom board three times with a sponge and a product called "Green Soap." (See below) |

|

| Issi makes sure I'm doing it right. |

|

| I show everyone my jello mold and talk about the importance of "well-drafted" surfaces in both models and molds. |

|

| A bottle of "Green Soap." Ask a pharmacist if he/she can order some for you. They'll be surprised that anyone under 70 knows what this is, let alone wants to use it. |

|

| We use Green Soap in moldmaking as a release agent with plaster. |

|

| We use the "Island Method" of mixing our Pottery Plaster. One container of water... |

|

| I use a metal sifter to mix my plaster into the water - this will break up any plaster chunks. |

|

| Slosh slosh slosh.... |

|

| As the plaster begins to set, it starts to hold its own shape. I can still scoop it up and use it to build onto the surface of the mold. |

|

| Smoothing the outside of the mold. |

|

| Later on that night: I release the foam hand from the alginate mold. Insert your stick between the alginate and the plastic mother mold to release the alginate from the mother mold. |

|

| Gently open the alginate mold. Go easy so as not to break the foam fingers. |

|

| Beautiful! Robert's foam hand emerges with all of its digits perfectly formed! |

No comments:

Post a Comment